- Power Cord

- America Power Cords

- Europe Power Cords

- Australia Power Cords

- UK Power Cords

- Korean Power Cords

- Japan Power Cords

- Italy Power Cords

- South Africa Power Cords

- Swiss Power Cords

- Argentina Power Cords

- Brazil Power Cords

- Israel Power Cords

- Denmark Power Cords

- China Power Cords

- Russia Power Cords

- Singapore Power Cords

- Saudi Power Cords

- Indonesia Power Cords

- Thailand Power Cords

- IEC 60320 Power Cords

- Locking Power Cord

- Dryer Power Pord

- Industry Plug

- Extension Cord

- Rubber Insulated Sheathed Flexible Cord

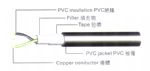

- PVC Flexible Power Cable

- Power Strip

- Power Cord

- America Power Cords

- Europe Power Cords

- Australia Power Cords

- UK Power Cords

- Korean Power Cords

- Japan Power Cords

- Italy Power Cords

- South Africa Power Cords

- Swiss Power Cords

- Argentina Power Cords

- Brazil Power Cords

- Israel Power Cords

- Denmark Power Cords

- China Power Cords

- Russia Power Cords

- Singapore Power Cords

- Saudi Power Cords

- Indonesia Power Cords

- Thailand Power Cords

- IEC 60320 Power Cords

- Locking Power Cord

- Dryer Power Pord

- Industry Plug

- Extension Cord

- Rubber Insulated Sheathed Flexible Cord

- PVC Flexible Power Cable

- Power Strip

Japan Power Cord Standard

Japan JIS C 8303 PSE Power Cord,Plug,Flexible Cable

The Japanese plug and socket appear physically identical to NEMA 1-15. The Japanese system incorporates stricter dimensional requirements for the plug housing, different marking requirements, and mandatory testing and approval by METI or JIS. Older Japanese sockets and multi-plug adapters are unpolarized—the slots in the sockets are the same size—and will accept only unpolarized plugs. Japanese plugs generally fit into most North American sockets without modification, but polarized North American plugs may require adapters or replacement non- polarized plugs to connect to older Japanese sockets. In Japan the voltage is 100 V, and the frequency is 50 Hz (East Japan) or 60 Hz (West Japan). Therefore, some North American devices which can be physically plugged into Japanese sockets may not function properly. JIS C 8303, Class I earthed Japan also uses an unearthed plug similar to the North American NEMA 5-15.[57] However, it is less common than its NEMA 1-15 equivalent. Since 2005, new Japanese homes are required to have class I earthed sockets for connecting domestic appliances. This rule does not apply for sockets not intended to be used for domestic appliances, but it is strongly advised to have class I sockets throughout the home

|

1. Plug Guide 2. Power Cord 3. Extension Cord 4. Flexible Cable 5. Certification 6. Reference |

Plug Guide

|

| Japan Plug Alligator Clip |

These bumps fit into the holes so that the outlet can grip the plug’s prongs more firmly. This prevents the plug from slipping out of the socket due to the weight of the plug and cord. It also improves the contact between the plug and the outlet. Some sockets, however, do not have those bumps but just two spring-action blades that grip the sides of the plug pin, in which case the holes are not necessary. There are also some special outlets which allow you to lock the cord into the socket, by putting rods through the holes.

In this way, vending machines and the like cannot be unplugged. Moreover, electrical devices can be factory-sealed by the manufacturer using a plastic tie or a small padlock through one or both of the plug prong holes. For example, a manufacturer might apply a plastic band through the hole and attach it to a tag that says: “You must do X or Y before plugging in this device”. The user cannot plug in the device without removing the tag, so the user is sure to see the tag. Type A and B plugs are not insulated (i.e. the pin shanks do not have a black covering towards the plug body like type C, G, I, L or N plugs) and the outlets are not recessed into the wall, which means that if a the plug is pulled halfway out, its prongs are still connected to the socket.

Since the distance between the receptacle and the plug is too small to touch the pins with your fingers, there is relatively little danger of electric shock. TYPE B electricity - type B (plug) (used, for instance, in North and Central America and Japan) (Click here for a complete list of all countries that use type B) electricity - type B (socket) This class I plug is designated as American standard NEMA 5-15. It has two flat 1.5 mm thick blades, spaced 12.7 mm apart, measuring 15.9 – 18.3 mm in length and 6.3 mm in width. It also has a 4.8 mm diameter round or U-shaped earth pin, which is 3.2 mm longer than the two flat blades, so the device is grounded before the power is connected. The centre-to-centre distance between the grounding pin and the middle of the imaginary line connecting the two power blades is 11.9 mm.

The plug is rated at 15 amps. In some parts of Central and South America, grounded type B outlets are still rather uncommon. Therefore people often simply cut off the earth pin of a type B plug in order to mate it with a two-pole ungrounded socket. Type A and B plugs are not insulated (i.e. the pin shanks do not have a black covering towards the plug body like type C, G, I, L or N plugs) and the outlets are not recessed into the wall, which means that if a the plug is pulled halfway out, its prongs are still connected to the socket. Since the distance between the receptacle and the plug is too small to touch the pins with your fingers, there is relatively little danger of electric shock.

Power Cord

Extension Cord

Japan Extension cord products with PSE JET certification are manufactured to JS C 8303 standards designed for Japanese extension cord applications,We are producing two and three prong Japan extension cords in standard configurations and can make any custom version as well.100% of our Japan power extension cords are fully molded high quality cords and RoHS and REACH compliant as We are China leading Japan extension cords manufacturer and supplier providing cheapest prices of Japanese PSE JET approved extension cord with good quality.mains products: Extension cord plug,extension power cord,extension socket,outdoor extension cord,outlet cord,outlet power extension cords。

Certification

Japan JIS C 8303 PSE approved for plugs,sockets and Flexible Cables.

Reference

1 . Catalog Japan (PDF - 207KB) Japan type power supply cords,plug and extension sockets.2 . Catalog Europe and Other Countries Product catalog of plugs and socket worldwide except US items.

- Contact Us

- Simen Twon,Yuyao City,Zhejiang,China,315472

- 86-0574-62162348

- 86-0574-62160100

- [email protected]

- hoobo.show1

- Terms and Conditions

- Privacy Statement

- Need help

- Home

- About us

- Products

- Download

- News

- Equipments

- Tech-Documnets

- Contact

- Products

- Power Cord

- IEC 60320 Power Cords

- Locking Power Cord

- Dryer Power Pord

- Industry Plug

- Extension Cord

- Rubber Insulated Sheathed Flexible Cord

- PVC Flexible Power Cable

- SUBSCRIBE

- Join us and get detail information,technical parameter and new products etc.

- [email protected]

- hoobo.show1

- 86-0574-62162348

- 86-0574-62162348