86-0574-62162348

Categories

- Power Cord

- America Power Cords

- Europe Power Cords

- Australia Power Cords

- UK Power Cords

- Korean Power Cords

- Japan Power Cords

- Italy Power Cords

- South Africa Power Cords

- Swiss Power Cords

- Argentina Power Cords

- Brazil Power Cords

- Israel Power Cords

- Denmark Power Cords

- China Power Cords

- Russia Power Cords

- Singapore Power Cords

- Saudi Power Cords

- Indonesia Power Cords

- Thailand Power Cords

- IEC 60320 Power Cords

- Locking Power Cord

- Dryer Power Pord

- Industry Plug

- Extension Cord

- Rubber Insulated Sheathed Flexible Cord

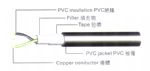

- PVC Flexible Power Cable

- Power Strip

pleated filter cartridge factory

high flow filter cartridge

large flow filter cartridge

membrane pleated filter cartridge

capsule filter suppliers

capsule filter 0.2 micron

capsule filter price

pvc dildo

fat pocket pussy

lamb skin dildo

mushroom head dildo

huge dildo

water filter cartridge

- Power Cord

- America Power Cords

- Europe Power Cords

- Australia Power Cords

- UK Power Cords

- Korean Power Cords

- Japan Power Cords

- Italy Power Cords

- South Africa Power Cords

- Swiss Power Cords

- Argentina Power Cords

- Brazil Power Cords

- Israel Power Cords

- Denmark Power Cords

- China Power Cords

- Russia Power Cords

- Singapore Power Cords

- Saudi Power Cords

- Indonesia Power Cords

- Thailand Power Cords

- IEC 60320 Power Cords

- Locking Power Cord

- Dryer Power Pord

- Industry Plug

- Extension Cord

- Rubber Insulated Sheathed Flexible Cord

- PVC Flexible Power Cable

- Power Strip

Future Products

power cord cooling apparatus for a vacuum cleaner

The power cord cooling apparatus may include an isolating wall to partition off a contaminants collecting chamber from the cord reel chamber, the isolating wall having a cooling hole configured to allow fluid communication between the contaminants collecting chamber and the cord reel chamber; wherein outside air entering the cord reel chamber enters the center space of the cord reel and is discharged to the contaminants collecting chamber via the cord reel supporting unit, the duct member, and the cooling hole.

A vacuum cleaner typically includes a power cord that will be connected with an external commercial electric power source to receive electric power and a cord reel rotatably disposed inside the main body of the vacuum cleaner to wind the power cord in coils thereon.The user then connects the plug with the commercial electric power source, that is, an electrical outlet in a cleaning area, to supply electric power to the vacuum cleaner.

Accordingly, after the vacuum cleaner has been used for a long time, the heat generated by the power cord may cause the temperature of the power cord to rise as the power cord is wound around the cord reel. If the temperature rises enough, the sheath of the power cord or the plastic cord reel may melt, causing the power cord to stick together or even short circuit.

The cord reel may include a cylindrical member having a plurality of holes configured to allow fluid communication between the cord reel chamber and the center space of the cord reel, and a pair of disk members extending from opposite ends of the cylindrical member configured to hold the power cord therebetween.

The power cord cooling apparatus may also include a second partition wall disposed at a predetermined distance from the first partition wall in the cord reel chamber and the second flow guide disposed between the first partition wall and the second partition wall.

A vacuum cleaner typically includes a power cord that will be connected with an external commercial electric power source to receive electric power and a cord reel rotatably disposed inside the main body of the vacuum cleaner to wind the power cord in coils thereon.The user then connects the plug with the commercial electric power source, that is, an electrical outlet in a cleaning area, to supply electric power to the vacuum cleaner.

Accordingly, after the vacuum cleaner has been used for a long time, the heat generated by the power cord may cause the temperature of the power cord to rise as the power cord is wound around the cord reel. If the temperature rises enough, the sheath of the power cord or the plastic cord reel may melt, causing the power cord to stick together or even short circuit.

The cord reel may include a cylindrical member having a plurality of holes configured to allow fluid communication between the cord reel chamber and the center space of the cord reel, and a pair of disk members extending from opposite ends of the cylindrical member configured to hold the power cord therebetween.

The power cord cooling apparatus may also include a second partition wall disposed at a predetermined distance from the first partition wall in the cord reel chamber and the second flow guide disposed between the first partition wall and the second partition wall.

- Contact Us

- Simen Twon,Yuyao City,Zhejiang,China,315472

- 86-0574-62162348

- 86-0574-62160100

- [email protected]

- hoobo.show1

- Terms and Conditions

- Privacy Statement

- Need help

- Home

- About us

- Products

- Download

- News

- Equipments

- Tech-Documnets

- Contact

- Products

- Power Cord

- IEC 60320 Power Cords

- Locking Power Cord

- Dryer Power Pord

- Industry Plug

- Extension Cord

- Rubber Insulated Sheathed Flexible Cord

- PVC Flexible Power Cable

- SUBSCRIBE

- Join us and get detail information,technical parameter and new products etc.

- [email protected]

- hoobo.show1

- 86-0574-62162348

- 86-0574-62162348